The 3D printing sector is in full growth and various industries such as automotive, aerospace and architecture, among others, are betting on it. The main advantage of 3D printing is the ability to create complex customised designs in a very short period of time and at a low cost. Other advantages include the possibility of creating parts without the need for moulds or producing efficiently without waste. In short, the 3D printing industry is revolutionising the way companies manufacture their products, and the latest innovations make it more accessible and cost-effective than ever before.

Bioplastics such as ADBioplastics’ PLA-Premium are optimal for 3D printing thanks to their optimised properties that bring greater ease and processability to both the filament production process and 3D printing itself. PLA-Premium is a sustainable alternative as it is compostable and bio-based, in fact, the material disintegrates in 3 months under industrial composting and leaves no trace of waste. ADBioplastics offers customised solutions with its different PLA-Premium grades according to each customer’s needs . Our advanced formulation allows for better printability than virgin PLA and has some superior characteristics to other 3D printing thermoplastics such as ABS or PP.

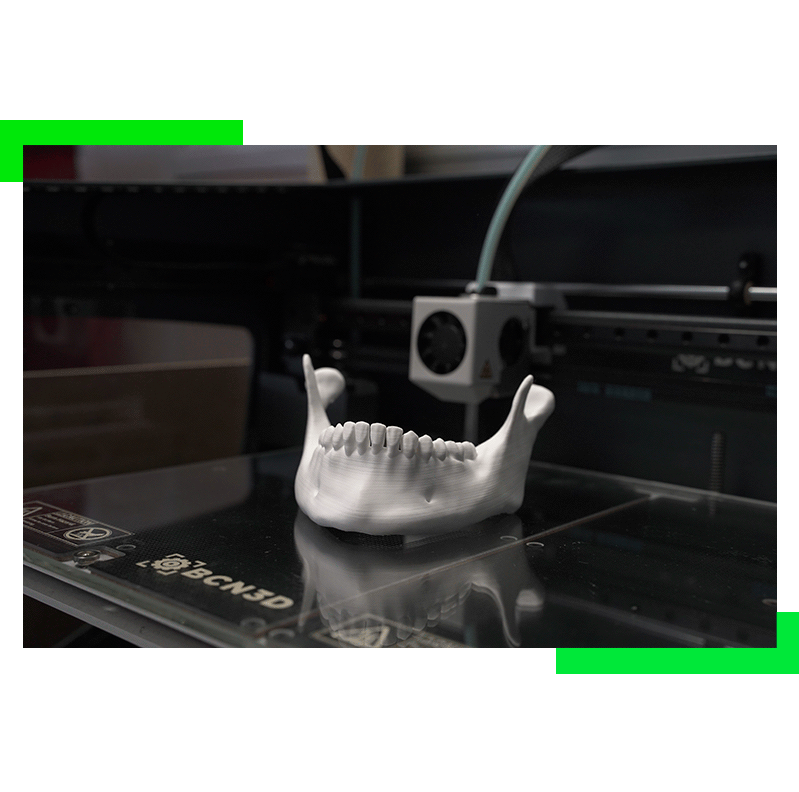

For 3D printing we have 3D filament extrusion technology, which allows us to adapt the material to the customer’s needs. In addition, we have customised grades to achieve the perfect formulation, obtaining a PLA without limits. In addition, our material allows the incorporation of various substrates such as wood, carbon fibre, carbonates, silicates, etcetera. Taking this into account, we can find:

PLA-Premium bioplastic, derived from renewable sources such as corn or sugar cane, offers an ideal base for rapid prototyping. Its printability and biocompatibility make it a popular choice for efficiently perfecting models .

Being compostable, safe for skin contact and suitable for food contact (FCM) and cosmetics, it is an ideal material for the manufacture of medical devices, sustainable packaging, toys, consumer goods and contemporary art and design.

ADBioplastics manufactures thermoplastic PLA-Premium filament spools for 3D printing that can be used in conventional equipment with optimal processability and possess unique properties compared to conventional plastics.

We have technical documentation just a click away so you can discover all the details about our value proposition. Click on the document that interests you the most!

Contact our experts and get the answers to your needs. We accompany you throughout the testing, sales and after-sales processes and give you personalised attention.