Success stories developed with bio-based and compostable materials for various application industries were showcased, promoting the adoption of sustainable solutions for a circular economy in the market.

ADBioplastics, a manufacturer and marketer of advanced and compostable additives and bioplastics, participated in the K 2025 international trade fair in Düsseldorf, Germany, from 8 to 15 October. the world’s leading showcase for the plastics industry, where it will showcase its latest innovations in compostable bioplastics based on polylactic acid (PLA) for industries such as food, cosmetics, textiles, agriculture, consumer goods and 3D printing.

Under the slogan ‘PLA without limits’, ADBioplastics presented at its stand the advances and success stories in the industry of its ADBio PLA+, a patented multifunctional additive that, when combined with virgin PLA bioplastic, creates PLA-Premium bioplastic with improved mechanical, barrier and processability properties, while maintaining the compostability, recyclability and transparency of the original biopolymer.

A market in transformation: bioplastics with a promising future

The bioplastics sector is undergoing rapid expansion, driven by regulatory pressure, consumer demand and the decarbonisation commitments of large companies. In fact, PLA is currently the biopolymer with the highest annual growth rate (CAGR), backed by European directives on single-use plastics, international bans and industrial and domestic compostability certifications.

In this context, companies that innovate in R&D to achieve functional and competitive alternatives to fossil-based plastics are positioning themselves as key technology partners to facilitate the transition to more environmentally friendly materials. None of this would be possible without the collaboration of leading companies in the development of real products already on the market that are driving their circular economy strategies.

In this regard, the PLA-Premium bioplastic developed by ADBioplastics is breaking with the traditional limitations of pure PLA, achieving up to 7 times greater impact resistance, improving flexibility without losing rigidity in rigid packaging, increasing the oxygen and water vapour barrier by up to 30%, which is key in food packaging, and optimised processability in conventional injection and extrusion equipment, reducing cycle times and costs. The material is OK Compost Industrial certified by TÜV Austria, guaranteeing the disintegration of its basic components within three months under industrial composting conditions.

Presentation of sustainable success cases in the industry

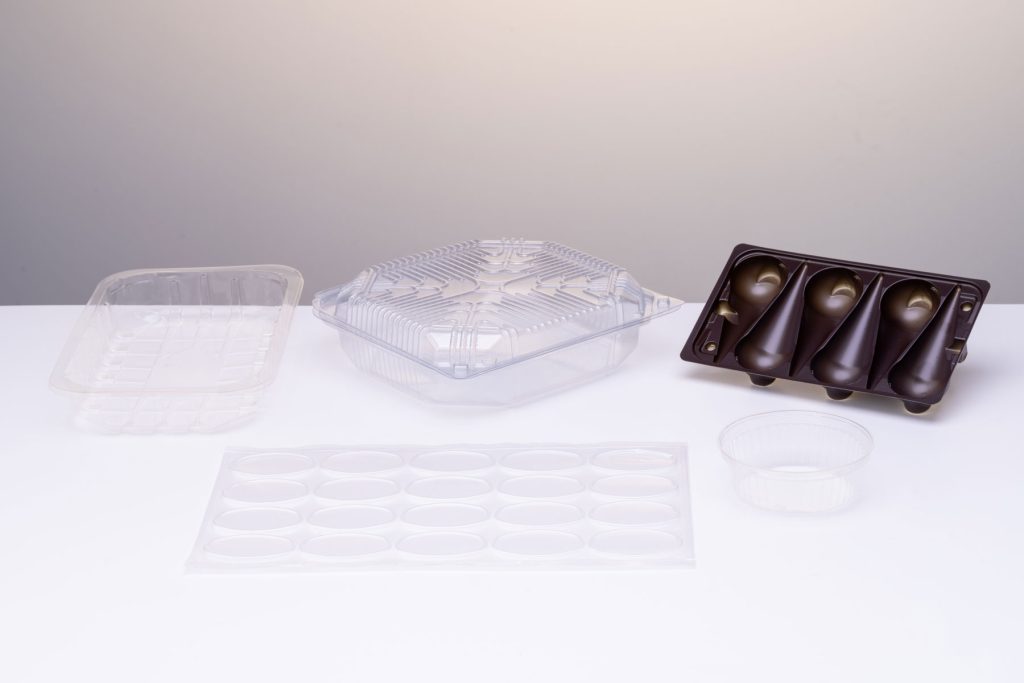

Among the developments that ADBioplastics showcased in Düsseldorf are cosmetic packaging, such as compostable bottles for shampoo and shower gel; food packaging, such as single-dose tubs for extra virgin olive oil; textiles, such as sustainable textile monofilament manufactured using non-woven extrusion technology; 3D printing, such as technical pieces for decoration and the home; and agriculture and consumer goods, such as BioLoop Band, a compostable filament that acts as a twistband closure without a metal core for tying vines, closing food containers and securing toys, electronics and tools in packaging.

Thermoformed trays and parts made from compostable PLA-Premium bioplastic for the food industry.

This technology enables companies to take a real step towards circularity, with compostable materials that match the performance and functionality of fossil-based plastics, but with a much lower environmental impact.

All these developments were displayed at booth 8AC34 at the K 2025 trade fair. With this participation, ADBioplastics reaffirms its role as a European leader in the development of advanced bioplastics and its mission to lead the transformation of the plastics industry towards a more sustainable and circular model.

Further information can be found on the ADBioplastics website or on its exhibitor profile at the K trade fair.

*New published in Industria Química, Industry Europe, Alimarket, Equipack, K 2025 trade fair, Revista Packaging and Additive-Fertigung.